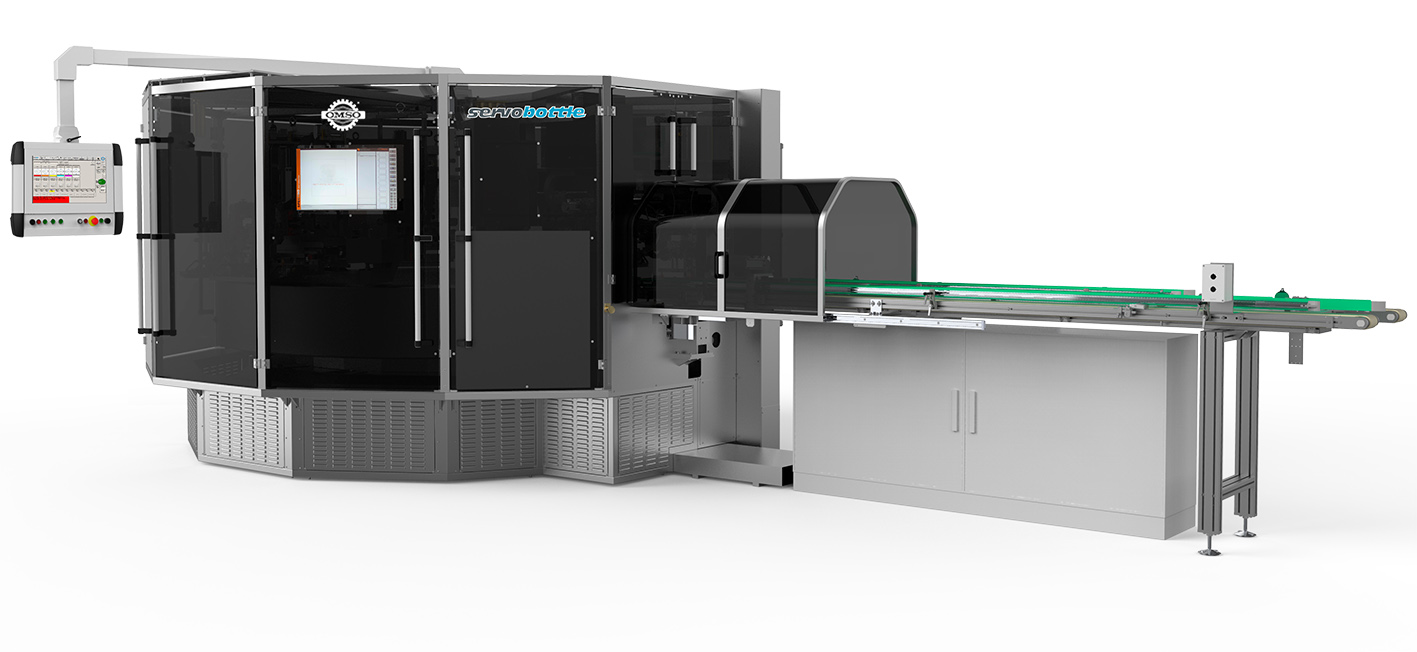

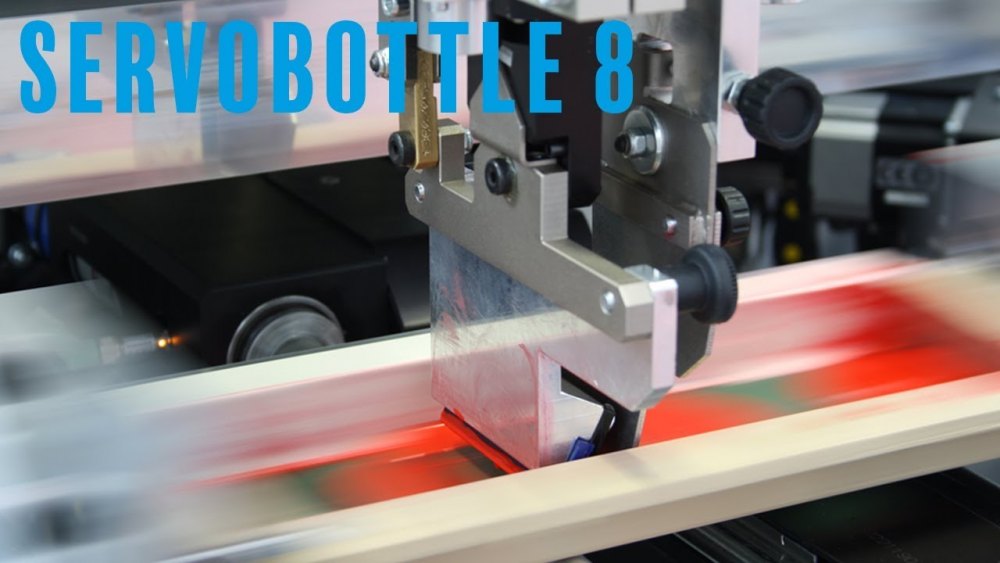

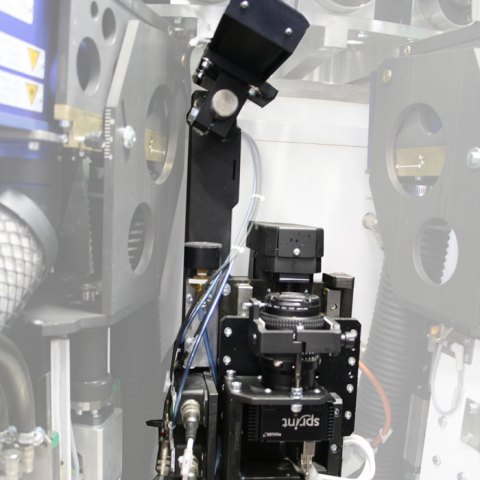

Automatic screen printing machine completely power-assisted for printing up to 10 colours in UV ink on multi-format glass / plastic bottles and containers.

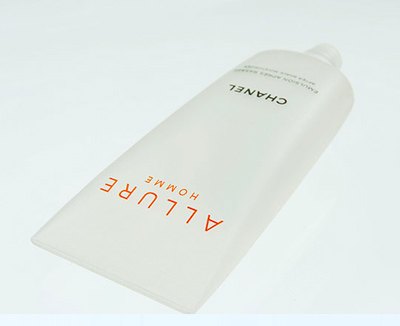

Completely servo-assisted, it can print up to 10 colours on plastic or glass multi-format containers.

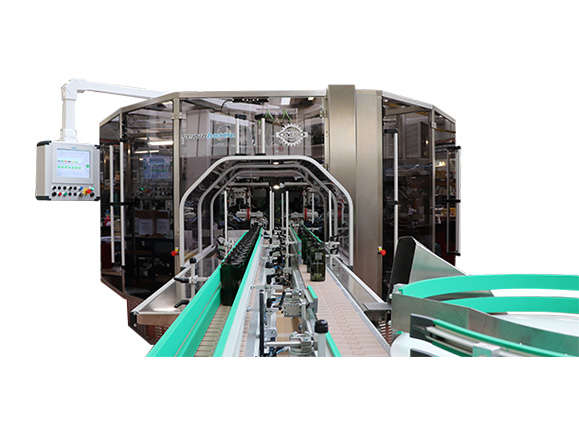

Stand alone or in line to complete the Servobottle packaging line, it exploits a Software designed to be integrated with industrial software packages focussed on optimising productive activities (industry 4.0).

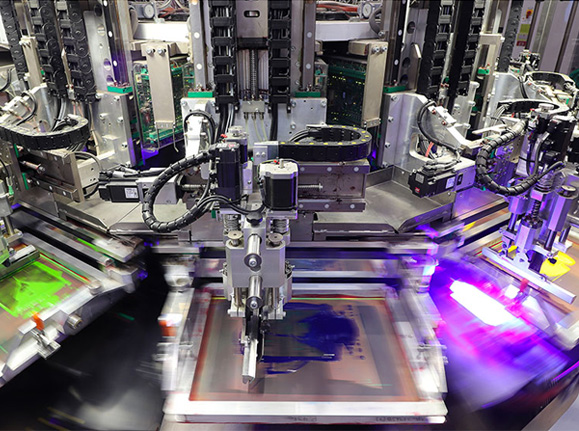

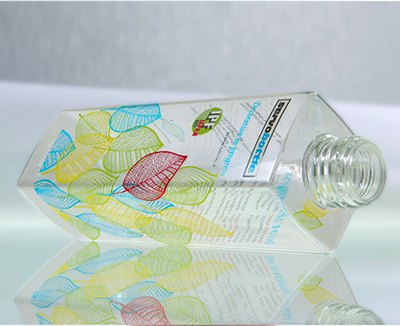

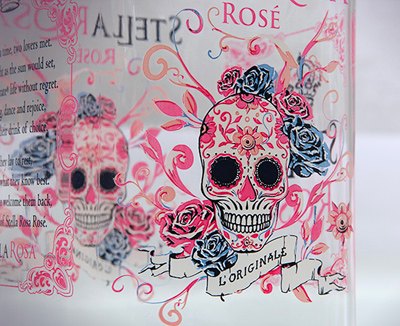

High printing quality on glass and plastic, thanks to servo-assisted printing adjustments that afford a 0.1mm adjustment tolerance between colours.

Reduced energy consumption thanks to the patented LED UV dynamic systems integrated in the printing station.

The integration of drying - on-the-fly drying systems gives the machine a compact look and reduced bulk.

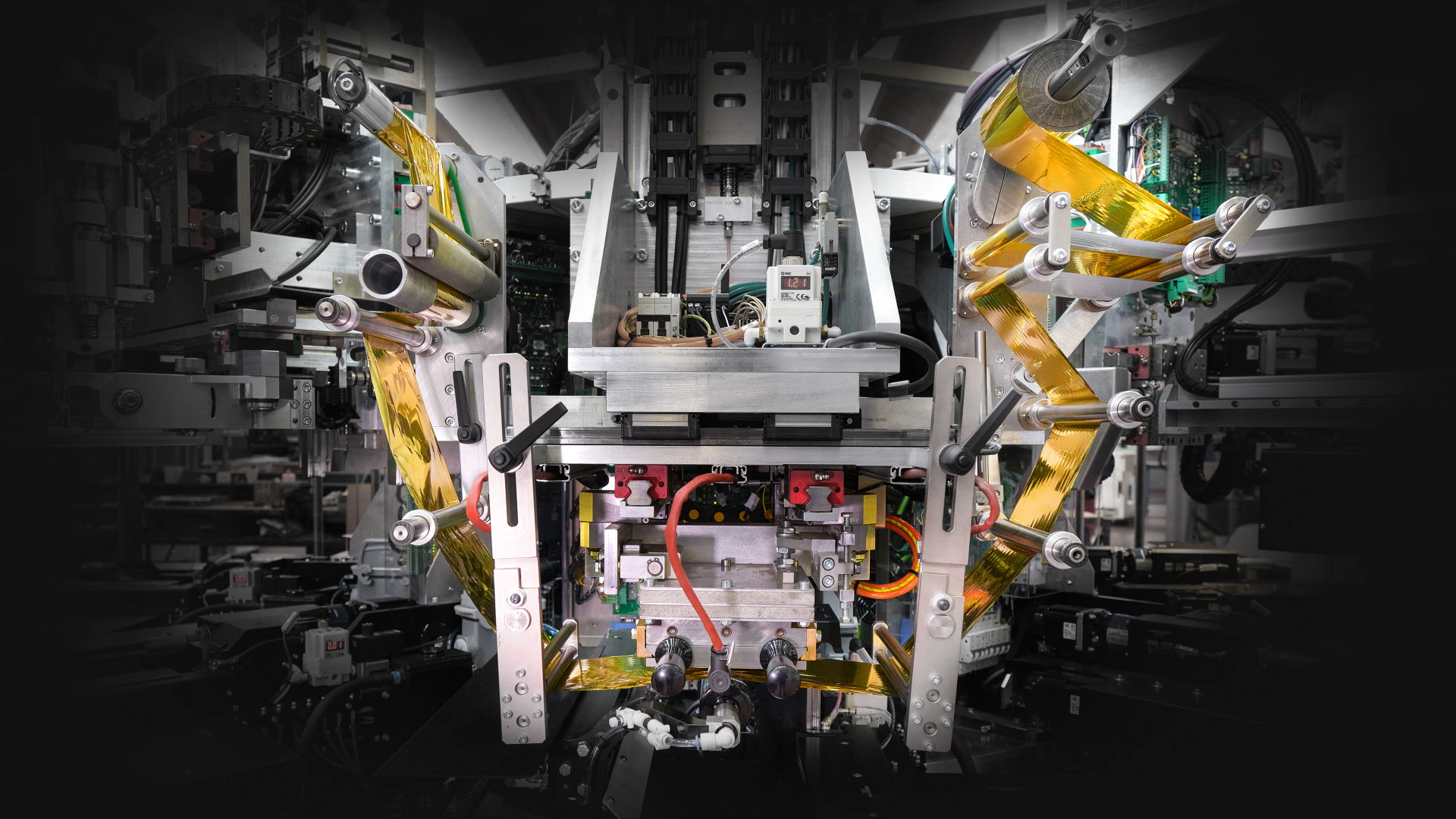

The machine can be equipped with the new hot stamping station for metallic gold and silver application on plastic products, which is interchangeable with a screen printing station.

The hot stamping station can also be added to machines already installed.

General Features :

- Max. production speed -> 90 pcs/min

- Minimum diameter -> 10 millimetres

- Maximum diameter -> 125 millimetres

- Oval minor axis, minimum -> 10 millimetres

- Minimum height -> 40 millimetres

- Maximum height -> 370 millimetres

- Maximum printing height -> 230 millimetres

- Maximum printing diameter at 360° -> 110 millimetres

- Maximum Hot Stamping height -> 100 mm

- Maximum Hot Stamping width ->125mm