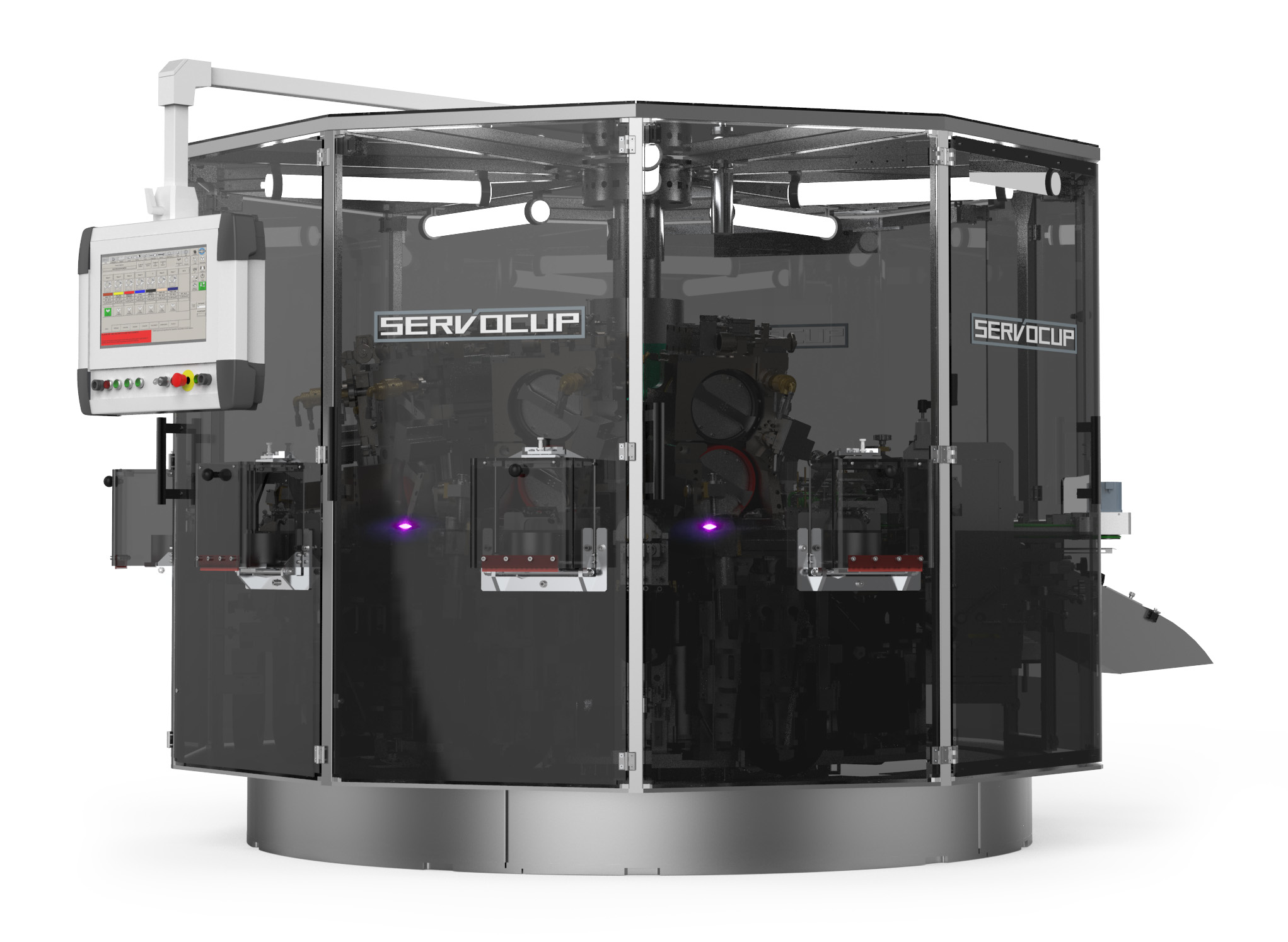

Innovation and precision in cup decoration

Based on a robust and precise platform with a 20-spindle turret, it achieves an output of up to 24,000 pieces/hour, guaranteeing photographic print quality and absolute repeatability.

The OMSO flexo system, combined with UV LED curing between stations, ensures brilliant colours, uniform coverage and no colour contamination.

UV LED curing: efficiency and sustainability

UV LED lamps bring concrete advantages over mercury vapour lamps such as:

• -75% energy consumption (measured with

LOVATO instrumentation on the 3 power phases)

• -75% CO₂ emissions

• Zero ozone production

• No maintenance,

• 10 times longer service life

• Immediate start-up, no warm-up time

LED curing between stations (print & dry system) enables true colour separation for high-definition images and photo-effect graphics.

Servocup UV LED is in full alignment with Regulation (EU) 2023/2049, which provides for the phasing out of mercury vapour lamps in industrial processes.

General characteristics:

• Min. cup diameter on edge -> 40 mm

• Max. cup diameter on edge -> 230 mm

• Min. cup height -> 40 mm

• Max. height of cup -> 230 mm

• Max. print height -> 180 mm

• Conicity -> 2° - 15°

• Max. production speed up to -> 24,000 pieces/hour (depending on container size and quality)