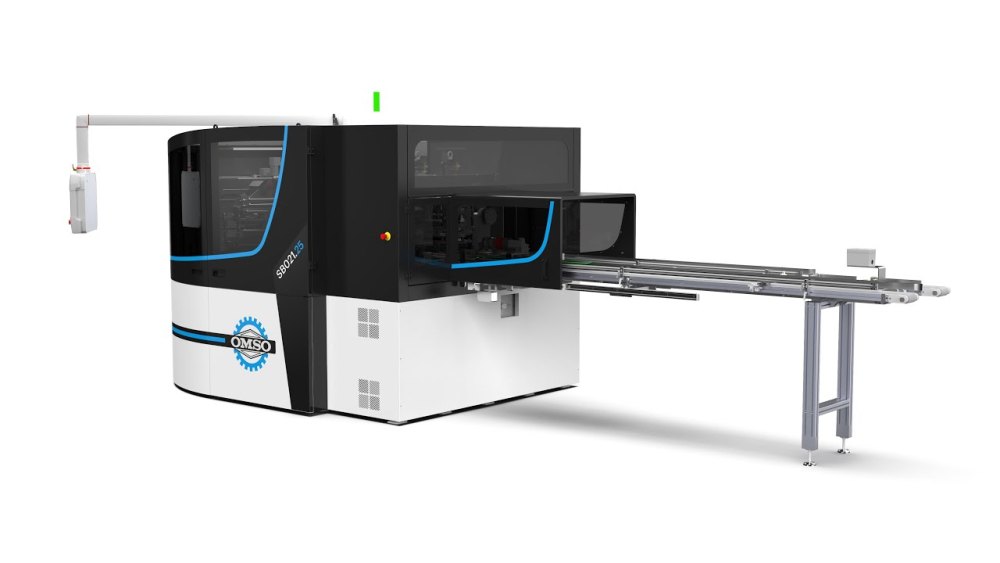

Precision, versatility and luxury finishes in one machine

The SB021.25 is the evolution of the SB021 platform, designed for direct decoration of cylindrical or shaped plastic or glass objects.

This version includes a hot stamping station for the application of gold, silver or metallic foils directly in-line, while maintaining the ability to decorate up to two screen printing colors.

It is the ideal solution for the cosmetic, pharmaceutical and luxury sectors, where aesthetics and quality must go hand in hand with productivity and sustainability.

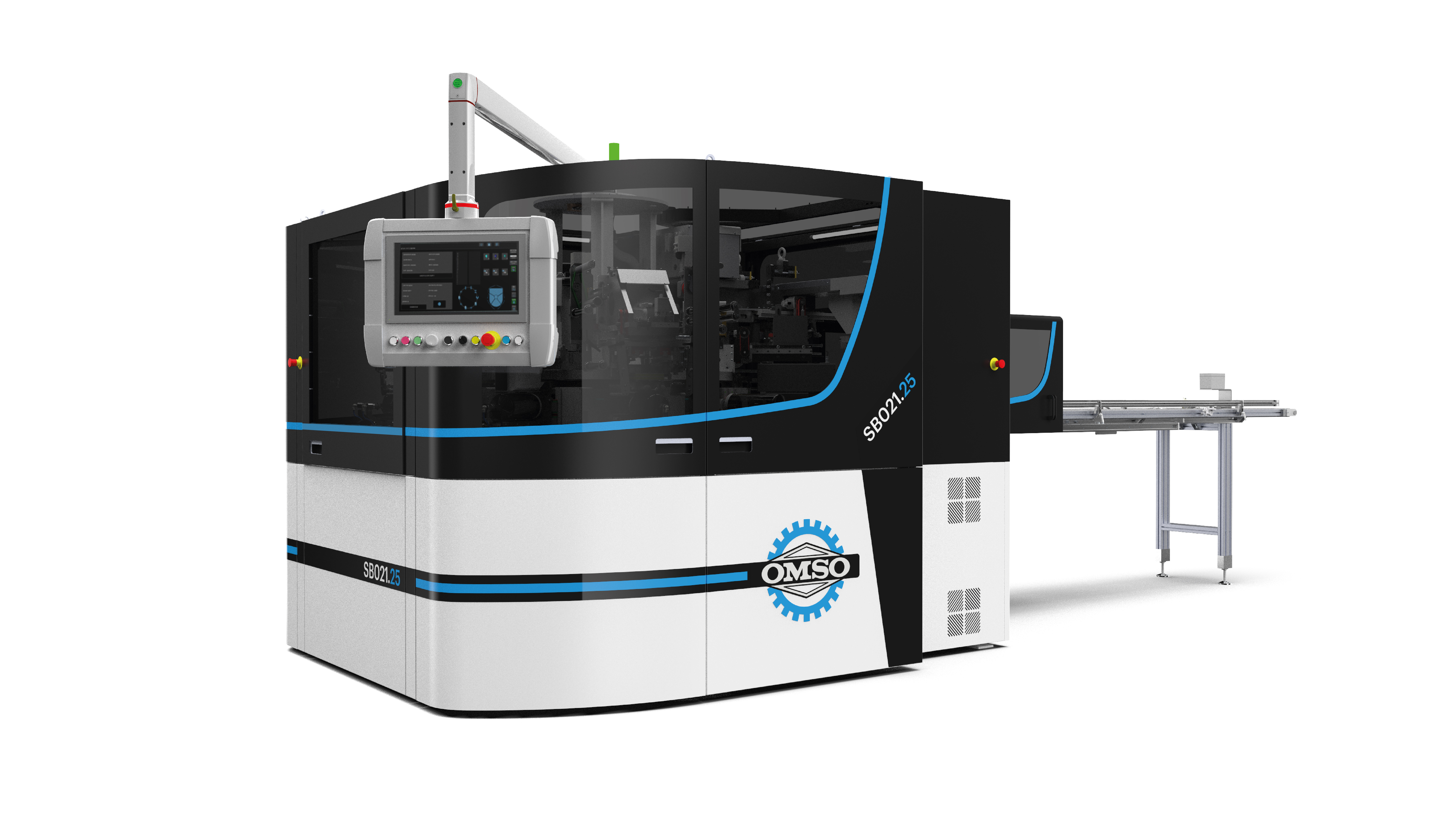

Main advantages

- Screen printing from 1 to 3 colors (up to 2 in combination with hot stamping)

- 360° decoration on cylindrical and shaped objects

- Built-in hot stamping station

- Quality control system for zero-defect productions

- Flexible configuration and fast format changeover

- Servo-driven technology for maximum precision

- Compact, efficient and reduced energy consumptions.

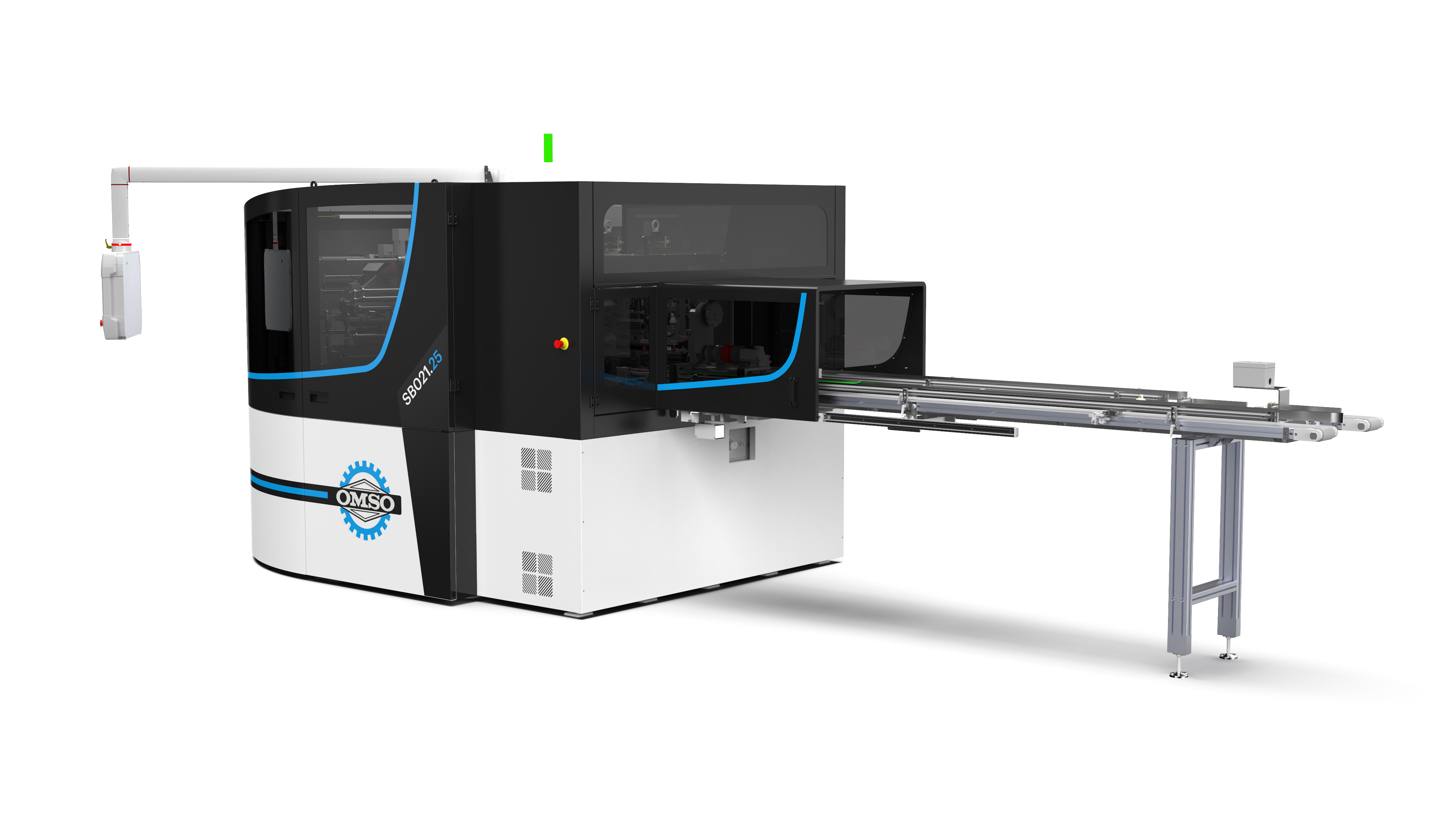

General features:

- Max production speed: 60pcs/min

- Minimum diameter -> 10 mm

- Maximum diameter -> 110 mm

- Oval minor axis, minimum -> 10 mm

- Minimum object height -> 20 mm

- Maximum object height -> 280 mm

- Maximum print height ->215 mm

- Maximum printing length ->251 mm

- Maximum hot stamping height ->110 mm

- Maximum hot stamping length ->95 mm

Calculate consumptions and evaluate savings

Consumptions

Savings